How are globes produced? Here, we reveal the manufacturing process used to make globes. If you haven’t yet done so, check out our article that highlights how maps are created for the surface of a globe.

Globes are made primarily in three different modes. The most common is vacuum formed, then press formed and finally hand-cut and applied, reserved for your higher-end models due to the handcrafted nature. Here are how these types of production methods form world globes.

VACUUM FORMED

The vacuum formed technique is the standard method to produce mechanically made globes. First, a distorted map is printed generally on pliable vinyl, which then is smoothed out in a second production step; finally, the world map will be bonded onto a half globe shell.

The northern and the southern hemisphere are created at different times and then combined to make the complete globe later on in production when they are glued or snapped together.

This style is a common way to make an illuminated floor, and desk globes as the inner shell are clear or white acrylic, allowing the internal light system to shine through the globe ball.

PRESS FORMED

A technique mainly still in use by Replogle Globes is where the northern and southern hemispheres start with a flat map applied to a thin piece cardboard/fiberboard and then several layers of cardboard added underneath to provide thickness and stability once formed. This flat map configuration is then pressed into a half-round sphere to create a hemisphere. The northern and southern hemispheres, which are manufactured separately, are then glued together at a later time. Equator tape is attached to hide the seam.

The primary purpose of using this production method is to create raised relief, which appears as small bumps and ridges on the surface of a globe to depict mountain ranges and topographical features.

Although this is a time tested and acceptable way to create a globe, some customers complain about alignment related issues with text and printed features where the individual pieces of the map come together.

HAND CUT & APPLIED

Globes that have the hand-cut and applied method are typically the most sought out as true-globe artisans handcraft them. They are also some of the most expensive.

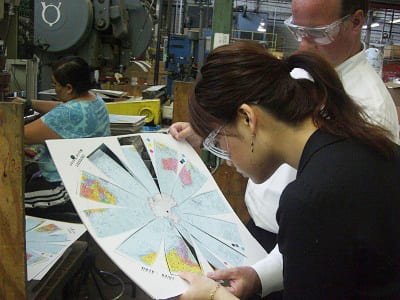

In this method, a manufacturer will use either an acrylic sphere or a hand-blown crystal sphere as its canvas. From there, a flat map is cut into “gores” or strips that look like diamonds with rounded sides.

These gores are then hand-applied to the sphere to ensure proper alignment. Once dry, many coats of finishing products are placed over the map to keep it safe from the elements.

Most globes with hand-cut & applied maps include illumination, as the shell used, allows for the light to shine through. At this time, Columbus Globes manufactures both desk globes and floor globe styles in this method, and Replogle Globes produces a few of its larger floor globes this way.